It was like a very strange little picnic-for-one on a Saturday afternoon in Sutherland... Up inside the non-rotating structure, with a whole assortment of goodies packed especially for the occasion: air, water, soap, alcohol, various expressions of cotton wool, 3 cameras, a bedroom pillow, a large trash bag, & (of course) duct tape! The ergonomics were fairly dismal, despite having set the tracker to its minimum tilt to help level out the floor of the non-rotating structure. Being at an angle of about 30 degrees from the horizontal meant that everything had to be carefully wedged into place to avoid having stuff sliding around & either falling down the hole onto M5, or out the open access hatch on the downhill side. Luckily none of the tour groups that passed through the dome during the afternoon were aware that there was someone perched many metres above them, wearing a bright blue hairnet, rubber gloves, a face mask, a headlamp & fall-arrest gear clipped to a piece of the tracker (in case anything went badly while trying to restore circulation to their numb legs & feet after kneeling in there for hours).

|

| Workstation for the in situ cleaning of M5 |

By way of introductions, M5 is the last mirror in the telescope (the final surface that light reflects off of on its way out of the spherical aberration corrector, en route to the instruments). It's made of Zerodur & weighs 18 kg, has a diameter of 410 mm, a clear aperture of 375 mm & a 375.8 mm radius of curvature (hence its nickname "the salad bowl"). M5 was last cleaned in December 2009, while the SAC was off the telescope for the Image Quality Fix, so it badly needed a wash. This is only possible if both the RSS & the rotating structure (aka the payload) are off the telescope, or else if the SAC itself is on the ground. Hence we pounced on this opportunity to clean M5, which ought to give the overall throughput of the telescope a significant boost.

|

| Bath time for a filthy dirty mirror! |

The cleaning was an extremely slow & delicate process, so it was necessary to work in sectors. That allowed short breaks in between to regain mobility, & also to decant more of the cleaning fluids & to check in with Ant (who was down in the spectrometer room, sketching the payload!) to confirm that M5 & I were still alive & well up there.

|

| The most accessible part of the mirror was cleaned first & used to optimise the washing process |

A bulb was used to blow loose dirt off the mirror before the wash cycle began. Then the goal was to limit the amount of liquid involved in any given step, while still making sure that the dust & dirt was adequately softened & mobilised before trying to remove it. De-ionised (DI) water was dabbed onto a sector of the mirror using numerous Webril pads (lint free squares of cotton wool) folded in half & wet along the folded edge. The water loosens the dust & then the same technique was used to dab a sodium lauryl sulphate (soap) solution onto the wet area to help lift more of the dirt. Each pad was checked along the way to ensure that the coating was not being disrupted - fortunately it showed no signs of degradation.

|

| DI water & soap (sodium lauryl sulphate) dabbed all over a sector of the mirror to loosen the dirt |

A lot more DI water was then dabbed over the soapy area to soak up the worst of the dirt that had been lifted. More soap was then applied & the Webril pads were folded a second time to produce a smaller square that could be used to drag wipe the surface. This involves dragging the wet pad over the surface, but with no downward pressure applied (other than the weight of the wet cotton wool). The drag-wiping process was then repeated several times with DI water to again rinse away the soap & remaining dirt. Small lint-free cotton wipes were then used (folded in half) to dab the wet sector dry, before using fresh isopropyl alcohol to complete the drying.

|

| About to clean the last sector |

After completing the washing & drying, it was obvious that the alcohol had left a lot of streaks & colourful residues on the mirror. This was removed by wiping the surface again with DI water & then carefully dabbing up the moisture with the small cotton wipes (folded in half).

The cleaning took just 3 hours & went remarkably smoothly. The visual improvement is quite amazing & we can now look forward to establishing the associated throughput increase once we get back on-sky in a few weeks.

|

| M5 looking a lot more like it should |

But M5's not out of the woods. We already knew, from the only other time that the mirror was washed (in 2009) that the coating's not nearly as good as it ought to be. It has an enormous number of tiny pinholes all over the surface... They've been there from the start & we only see them again now that all the dust & dirt is no longer masking them.

|

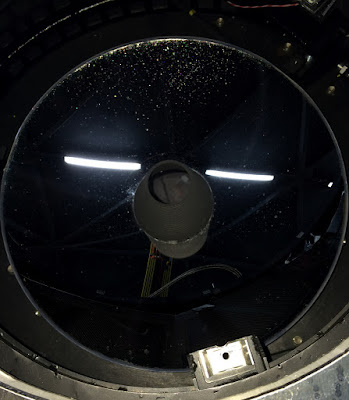

| Spot the plague of pinholes that mar the surface? |

The pinholes are a lot more obvious when photographed with a flash - this makes the mirror look like a dense region of the Milky Way, as viewed on a dark night in Sutherland :|

|

| Flash photography leaves the pinholes nowhere to hide now that the dust layer's no longer obscuring them |

We'll definitely need to re-coat M5 in the future, probably with a simpler coating & possibly even just with bare aluminium if it turns out that we can successfully coat a surface that's as optically fast (steep) as this in house. If we can make removing, re-coating & re-installing M5 (the most exposed of all the SAC mirrors) a routine operation, we'll be able to get SALT's throughput to a healthier level than it's ever been, & keep it there.

|

| The M5 coating's far from what it ought to be, but at least it's vastly better than it was |

For now though, the next task is to clean M4 & get it back where it belongs!

No comments:

Post a Comment